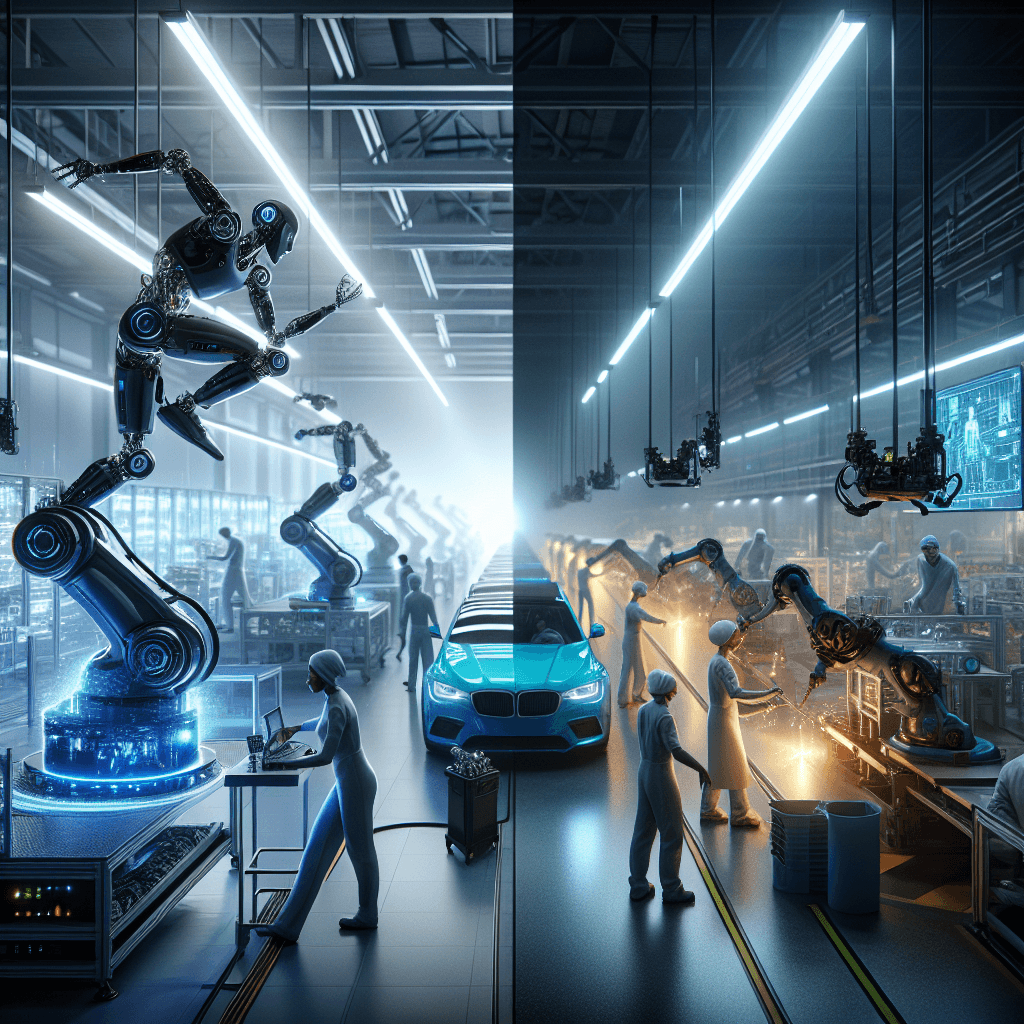

Remember when Boston Dynamics' Atlas doing backflips broke the internet? When warehouse robots navigating obstacle courses went viral on YouTube? That era is over. Not because the videos stopped being impressive, but because something more significant happened: those robots left the lab and got jobs.

If you're a technical leader evaluating automation strategies, January 2026 represents a watershed moment you can't afford to miss. For the first time, the technology stack underlying physical AI—foundation models, real-world training data, cost-effective actuators, and simulation platforms—has matured enough to deliver profitable operations at scale. This isn't speculation. It's happening right now on factory floors in Georgia, in logistics centers worldwide, and across industrial facilities that have moved beyond proof-of-concept.

The Infrastructure Shift: Why January 2026 Is Different

The difference between a technology demo and infrastructure is simple: infrastructure generates returns. It operates reliably in uncontrolled environments. It scales economically. And most importantly, someone is willing to bet their bottom line on it.

Boston Dynamics announced production manufacturing of Atlas—their fully electric humanoid robot—with immediate deployments scheduled at Hyundai and Google DeepMind facilities. A fleet is headed to Hyundai's Robotics Metaplant Application Center in 2026. According to Boston Dynamics, most customers should see return on investment within two years. Not five years. Not "eventually." Two years.

"The deployment of Boston Dynamics' electric Atlas at Hyundai's Georgia plant marks the definitive end to the era of robotics-as-entertainment and the beginning of robotics-as-infrastructure."

This ROI timeline matters because it fundamentally changes the business case. When you can project payback within 24 months, physical AI moves from the R&D budget to the capital expenditure conversation. CFOs start paying attention. Deployment timelines accelerate. Competitive dynamics shift.

What Changed Technically

Three technical breakthroughs converged to enable this transition:

Foundation models reached physical intelligence. Boston Dynamics partnered with Google DeepMind to integrate foundation models directly into Atlas. These aren't narrow task-specific algorithms—they're models that can generalize across manipulation tasks, understand context, and adapt to novel situations without complete reprogramming.

Actuator technology became production-ready. Hyundai Mobis is supplying actuators for Atlas, bringing automotive-grade manufacturing discipline to humanoid robotics. This partnership matters because automotive supply chains operate at entirely different scale and reliability standards than research labs. When tier-one automotive suppliers commit to component production, you know the technology has cleared serious validation hurdles.

Simulation platforms eliminated data bottlenecks. Training physical AI systems requires enormous amounts of real-world interaction data—traditionally the hardest bottleneck to overcome. NVIDIA's answer arrived at CES 2026.

NVIDIA Alpamayo: The Developer Platform for Physical AI

At CES 2026, NVIDIA unveiled Alpamayo—not a single model, but a comprehensive ecosystem for building physical AI systems. This release represents NVIDIA's strategic move beyond GPUs-for-training into end-to-end platforms for physical intelligence.

The scope is staggering:

- 10 trillion language training tokens

- 500,000 robotics trajectories

- 455,000 protein structures

- 100 terabytes of vehicle sensor data

For developers, this changes the game entirely. Previously, organizations building robotic systems faced a brutal choice: invest millions in data collection infrastructure or severely limit your system's capabilities. Alpamayo eliminates this bottleneck by providing open-source models spanning the Nemotron family for agentic AI, the Cosmos platform for physical AI simulation, Isaac GR00T for robotics, and Clara for biomedical applications.

Why Open Source Matters for Physical AI

NVIDIA's decision to release Alpamayo as open source isn't altruism—it's strategy. Physical AI requires domain-specific fine-tuning for virtually every deployment scenario. A humanoid working in automotive assembly faces different challenges than one in logistics or healthcare. By open-sourcing the foundation, NVIDIA enables rapid experimentation and specialization while positioning their hardware (Jetson for edge inference, DGX for training) as the natural platform choice.

For technical decision-makers, this approach offers significant advantages:

- Reduced vendor lock-in: You can evaluate and modify models without waiting for proprietary vendor releases

- Faster customization: Start with proven foundations rather than building from scratch

- Community-driven improvements: Benefit from optimizations and bug fixes across the ecosystem

- Transparent evaluation: Understand model capabilities and limitations before committing to deployment

"NVIDIA unveiled a major expansion of its open AI ecosystem designed to move AI beyond digital tasks and into systems that can perceive, reason, and act in physical environments."

CES 2026: From Demonstrations to Deployments

Walk the floor at any previous CES and you'd see impressive robot demos—carefully choreographed, operating in controlled environments, with engineers nervously hovering nearby. CES 2026 marked a departure from this pattern. Companies showcased robots that are shipping, deployed, or scheduled for real-world rollout in 2026 across factory floors, hospital environments, home kitchens, and service desks.

This distinction matters for technical planning. When evaluating physical AI for your organization, the relevant question is no longer "can this work in theory?" but rather "who else is already running this in production, and what are their results?"

The $16.7 Billion Validation

The global market value of industrial robot installations reached an all-time high of $16.7 billion, with future demand driven by technological innovations, market forces, and new business fields. This figure represents actual installations—not projected markets or addressable opportunities, but deployed systems generating value today.

For context, consider what this means for competitive dynamics in manufacturing, logistics, and service industries. Early adopters aren't experimenting anymore—they're scaling. They're achieving efficiency gains, improving safety metrics, and solving labor challenges that conventional automation couldn't address. Every quarter they operate with these advantages while competitors evaluate options represents growing competitive moat.

Practical Considerations for Technical Leaders

If you're responsible for automation strategy, infrastructure, or operations technology, here are the key evaluation criteria that matter right now:

Start With Use Case Economics, Not Technology Capabilities

Boston Dynamics' two-year ROI claim is use-case specific. Not every humanoid deployment will hit that timeline. Focus on scenarios where:

- Labor costs are high relative to task complexity

- The environment is already designed for human workers (eliminating facility redesign costs)

- Tasks require manipulation dexterity beyond conventional automation

- Safety or ergonomics create challenges for human workers

Evaluate Data Infrastructure Before Model Selection

Foundation models are powerful, but they require domain-specific fine-tuning. Before committing to physical AI deployment:

- Assess your ability to collect task-specific training data

- Evaluate simulation fidelity for your specific environment

- Plan for continuous learning and model updates post-deployment

- Consider data privacy and security implications for your industry

Build Cross-Functional Teams Early

Physical AI deployments fail when treated as pure technology projects. Successful implementations require:

- Operations expertise to identify high-value use cases

- Safety and compliance leadership to navigate regulatory requirements

- Facilities management for workspace integration

- Change management capabilities to address workforce concerns

Plan for Integration, Not Replacement

The most successful physical AI deployments augment existing workflows rather than wholesale replacement. Identify tasks where robots can:

- Handle repetitive heavy lifting while humans focus on quality control

- Work overnight shifts to maximize facility utilization

- Operate in hazardous environments unsuitable for human workers

- Provide consistent performance during demand peaks

The Strategic Window Is Open—But Not Indefinitely

Technology inflection points create temporary windows where early movers gain disproportionate advantages. We're in that window now for physical AI. The technology has proven viable. The economics are compelling for specific use cases. The platforms and ecosystems are in place.

But this window won't stay open forever. As more organizations deploy physical AI systems, several dynamics will accelerate:

- Best practices will solidify around implementation approaches, making it harder to differentiate through innovation

- Talent competition will intensify for engineers with physical AI deployment experience

- Supply chains will tighten as component demand surges and lead times extend

- Customer expectations will reset based on what leaders in your industry deliver

The question isn't whether physical AI will transform operations in your industry—it will. The question is whether your organization will lead that transformation, quickly follow, or struggle to catch up.

"We have entered the era of robotics-as-infrastructure. The robots aren't coming—they're here, they're working, and they're generating returns."

For technical leaders, the next steps are clear: identify high-value use cases, evaluate technology platforms against specific requirements, build cross-functional teams, and start small-scale deployments to build organizational capability. The organizations that move decisively in 2026 will define the competitive landscape for the next decade.

The era of viral YouTube videos is over. The era of profitable physical AI operations has begun. What role will your organization play?